Researchers at Delft University of Technology have developed novel cerium-doped indium oxides (ICO) for heterojunction solar cells, enabling significant improvements in power conversion efficiency through a transparent conductive oxide (TCO) built with the compound.

Scientists at TU Delft in the Netherlands fabricated a front-back contact silicon heterojunction (FBC-SHJ) solar cell using a TCO based on ICO, aiming to enhance the device’s opto-electrical performance. “To further increase power conversion efficiency, high-mobility TCO layers are key,” lead author Engin Özkol told pv magazine. “We explored cerium-doped indium oxide films for this purpose. Longi already uses hydrogenated indium oxides in its record-breaking cells via reactive plasma deposition, but we employed budget-friendly room-temperature radio frequency (RF) sputtering—widely accessible in labs but underused in literature.”

ICO layers are attractive for solar cell manufacturing due to their opto-electrical properties and room-temperature deposition, outperforming indium tin oxide (ITO) counterparts. The team sputtered 35-nm-thick ICO films onto Corning Eagle XG glass substrates at room temperature. “First, we optimized ICO layers for mobility, carrier concentration, resistivity, and transmittance,” said Özkol. “We achieved a Hall mobility of 44.22 cm²/Vs—56% higher than baseline ITO—and a resistivity as low as 8.56×10⁻⁴ Ω·cm. The next step was integrating this layer into solar cells.”

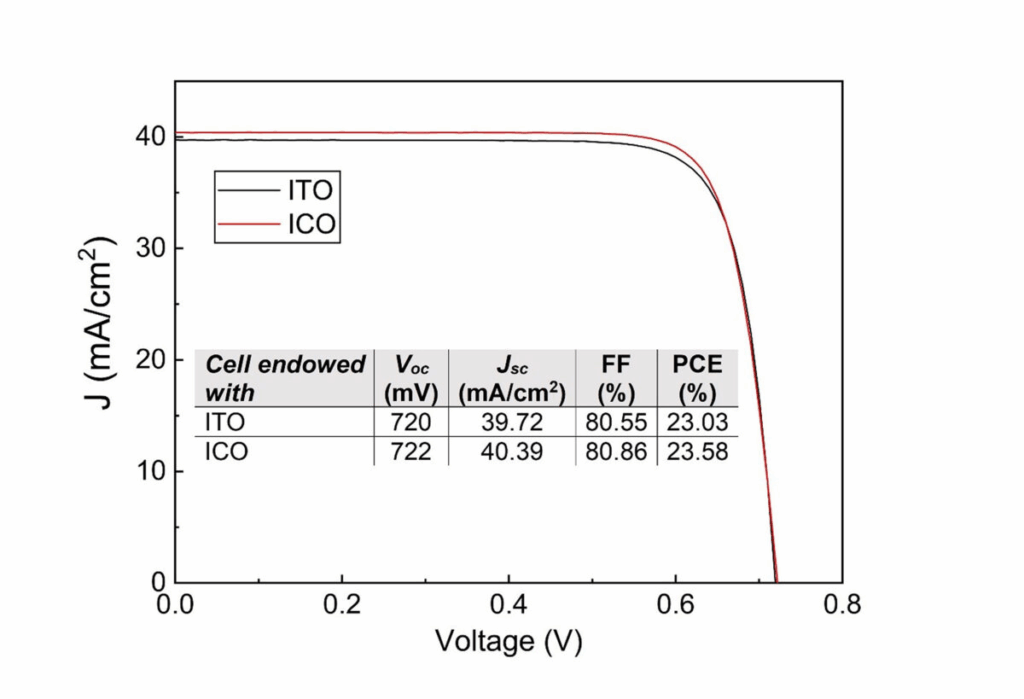

The team built 2×2 cm² cells on fully passivated 4-inch round wafers. Under standard illumination, the device achieved 23.58% power conversion efficiency, 722 mV open-circuit voltage, 40.39 mA/cm² short-circuit current, and 80.86% fill factor. A reference cell with ITO TCO reached 23.03% efficiency, 720 mV voltage, 39.72 mA/cm² current, and 80.55% fill factor. “The opto-electrical improvements of ICO over ITO translated to device-level gains, particularly a 0.67 mA/cm² increase in short-circuit current,” Özkol noted. “We demonstrated ICO’s potential as a powerful ITO alternative and opened pathways for cost-effective, scalable, low-temperature TCO fabrication in advanced PV technologies.”

The new cell concept is detailed in the study “Optimization and integration of room temperature RF sputtered ICO as TCO layers in high-performance SHJ solar cells,” published in Solar Energy Materials and Solar Cells. In April, other TU Delft researchers presented a rear junction silicon heterojunction solar cell with a localized front carrier-selective passivating contact, covering only metal grid contact areas.